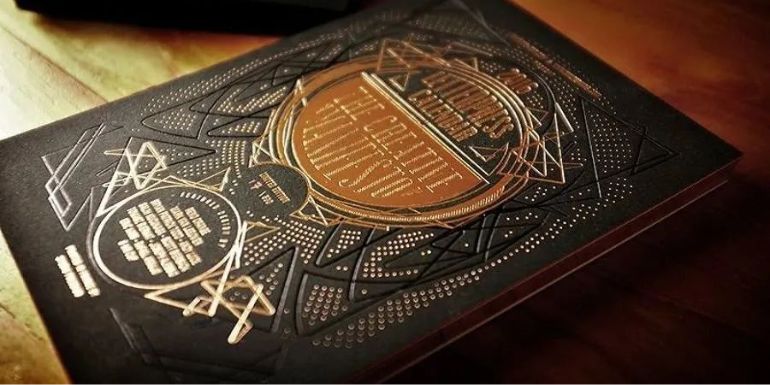

As a special printing technology that doesn’t use ink, hot stamping is eco-friendly and clean. It is suitable for various materials such as plastic, glass, and paper. Its popularity is attributed to the unique surface decoration effects achieved through hot stamping foil.

Hot stamping, also known as thermal transfer printing, is a special printing process that doesn’t involve ink. It utilizes templates loaded onto hot stamping machines, applying pressure and temperature to transfer metallic or pigment foils according to the design on the hot stamping template onto the surface of the printed material.

In a standardized sense, hot stamping refers to the thermal transfer printing process of hot stamping foil (also known as hot stamping paper) onto the surface of the substrate at a specific temperature and pressure.

Today, let’s delve into the world of hot stamping with KOMAI.

Features Of Hot Stamping

Hot stamping allows the printing surface to have patterns with a metallic texture in various colors. Additionally, it can combine different stamping effects. Besides its surface decoration function, hot stamping plays a crucial role in anti-counterfeiting.

Pros and Cons Of Hot Stamping

Pros:

- Full-surface hot stamping products leave no ink residue.

- No unpleasant ink odors, ensuring pollution-free air.

- Colorful patterns can be stamped in one go, reducing waste.

- Simple process, smooth production management, and efficient workflow ensure high product quality.

- Wide processing range, applicable to materials such as paper, wood, plastic, leather, etc.

Cons:

- Not suitable for substrates with uneven surfaces, presenting a rough or matte appearance.

- Generally not suitable for stamping on metal, glass, ceramics, nylon, etc., unless coated with paint or processed through screen printing.

- Matching the color of the pattern with the base color: the covering power of electrochemical aluminum (gold, silver, copper, inner red, inner blue) is strong, even covering black substrates; however, on a black base with light colors like white or yellow, the covering effect is not as good as with transfer printing or screen printing.

Main Equipment and Materials Used For Hot Stamping

Hot stamping primarily utilizes heating and pressure to transfer patterns or text onto the surface of the stamped material. To achieve this, hot stamping machines heat templates with specialized text or patterns (such as zinc plates or copper plates) to a specific temperature. Proper pressure is applied to ensure the complete transfer of the hot stamping foil, maintaining the corresponding time. It’s crucial to select different models of electrochemical aluminum foils for different materials, adjusting temperature, pressure, and stamping time during operation to achieve the desired hot stamping effects.

Equipment and materials used in hot stamping include hot stamping machines, hot stamping rubber plates, hot stamping dies, hot stamping wheels, foil cutting machines, hot stamping foil, rubber plates, rubber rollers, and other auxiliary materials.

Influencing Factors In Hot Stamping

In hot stamping, it is essential to choose suitable hot stamping foils based on the different varieties of stamped materials. The foils should be matched with appropriate paper, ink (especially black ink), kerosene, and composite glue. Stamped items must be kept dry to prevent oxidation or damage to the hot stamping layer.

Controlling the temperature, pressure, and stamping speed is crucial during hot stamping, varying based on the material and stamped area. Careful consideration is needed when cutting, controlling the speed and direction of the cutting tool. Proper storage of hot stamping foils is essential to prevent pressure, moisture, heat, and sunlight, storing them in a cool and ventilated place.

Many factors influence hot stamping quality, including hot stamping temperature, pressure, speed, equipment, substrate, operating techniques, and environmental factors, in addition to the hot stamping foil and hot stamping plate mentioned earlier.

Mastering the compatibility of hot stamping is critical to improving hot stamping quality. Compatibility refers to the selection of the appropriate model of electrochemical aluminum and the matching of hot stamping speed, temperature, and pressure.

Under fixed hardware conditions, correctly understanding compatibility is the most important means of improving hot stamping quality. Therefore, attention should be paid to the correct matching between different materials and the various processes before hot stamping and the application of new technologies and methods.

For example, direct hot stamping on the surface coated with UV varnish requires high requirements for both UV varnish and hot stamping electrochemical aluminum. During varnish application, controlling the amount of varnish is essential to ensure the relative stability of the entire batch of products.

Additionally, the varnish layer should be thin and even. As for the electrochemical aluminum used for hot stamping, it must withstand high temperatures, have excellent adhesion, and exhibit good compatibility with the varnish (the resin type used in varnish matches the hot melt adhesive in the hot stamping electrochemical aluminum). This technique has a limited application scope among all products.

Moreover, hot stamping on gold, silver ink, and matte oil also imposes high requirements on the surface and compatibility of the hot stamping electrochemical aluminum. Large ink particles or rough surfaces on the hot stamping surface directly affect the normal progress of hot stamping.

Applications Of Hot Stamping

Hot stamped graphics have a dazzling and magnificent visual effect, playing a role in enhancing the overall appearance of products. The application of hot stamping has now extended to various industries such as textiles, clothing, paper, plastic, glass, electronics, toys, gifts, and crafts.

Products processed through hot stamping not only have clear and beautiful patterns with vibrant colors but also exhibit durability and weather resistance. This process enhances the product’s level, aligning with current trends while adhering to the contemporary industrial concept of environmental protection. It has become an international trend.