The pricing of printing games can fluctuate due to numerous factors, encompassing raw material expenses, printing costs, finishing touches, packaging, and more. When combined, these elements contribute to the overall expenditure.

We have outlined the printing procedure and associated expenses for card games below. If you require further assistance in estimating the cost of printing your game cards, please don’t hesitate to reach out to us.

The Basics Of Card Printing Game Costs

Generally, the cost of the printed materials that constitute your Card Game comprises:

- Raw Materials Costs

The size and quantity of raw paper sheets are significant cost factors. Utilizing larger sizes or more raw paper will inevitably result in increased costs.

Within the paper industry, there are several standard sizes, with the most frequently employed ones by custom card printers being:

- 740x470mm blue core paper

- 740x510mm art paper

- 510x660mm black core paper

- 740x510mm white paper

Each of these dimensions can accommodate the printing of 55 poker-sized game cards (63x88mm) and can be efficiently printed using the Heidelberg 4mo machine, making it one of the most budget-friendly combinations.

If your cards are smaller or larger, rest assured that we will diligently seek the most cost-effective solution for your needs.

For substantially large order quantities, you have the option to request a custom size from our raw material supplier. However, many customers are often constrained by the standard paper sizes.

Therefore, your aim should be to minimize paper wastage by considering designs that align with conventional card sizes. Utilizing excess paper not only has environmental implications but also escalates the costs of your game card printing.

Additionally, please remember to incorporate a 3mm bleed on all sides of your artwork. Be sure to factor this bleed requirement into your paper size selection, using millimeters (mm) as the unit of measurement, rather than inches.

- Card Game Printing Costs

In general, it’s important to note that the setup fee tends to increase with larger printing formats. Startup costs primarily stem from expenses associated with creating plates, fine-tuning the press, and compensating operators during the printing process.

While many creators and industry experts might assume that the cost of a print is solely based on the price per print, this isn’t entirely accurate. Instead, a significant portion of the cost comprises fixed expenses related to plate creation and machine calibration.

Furthermore, it’s essential to take into account the wastage experienced by each machine, typically ranging from 15% to 30%, depending on the complexity of the printing job. This wastage is inevitable as machines undergo debugging and quality control processes.

As a result, you’ll observe that the per-unit cost of printing for a small print run is considerably higher than that for larger card game print runs spanning thousands of units. In fact, the total cost of printing 500 game sets may not differ significantly from the cost of printing 100 sets, as both require a similar amount of time and entail similar setup expenses.

We often utilize three types of printing presses along with their respective printing formats:

- Heidelberg Speedmaster 2mo machine: 1020×705 mm

- Heidelberg Speedmaster 4mo machine: 740×585 mm

- Heidelberg Versafire digital printer: 740×510 mm

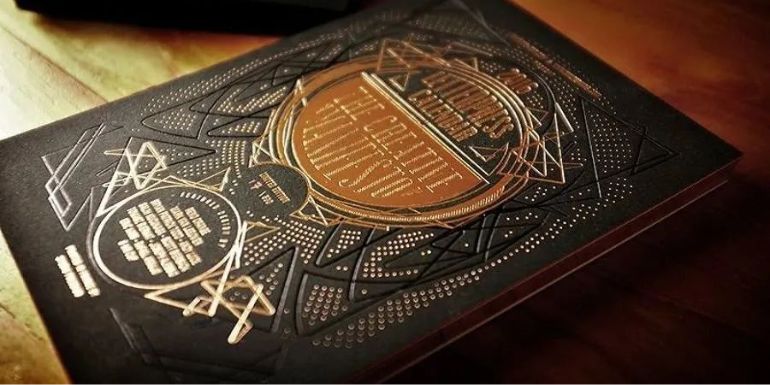

- Coating And Card Linen Finish

The cost of coating is influenced by the thickness and quality of the materials applied during this stage. Typically, lamination is more expensive than varnishing and is priced per square millimeter.

On the other hand, decorative coatings like hot stamping, spot UV, and others are priced based on the number of printed sheets. Similar to printing, most of these processes entail a setup fee.

- Cutting And Gluing

The cutting process primarily involves the precision cutting of cards and cardboard for boxes. As long as the card size falls within a reasonable range (for example, not too small, such as 25x100mm or 41x63mm), the machine can automatically handle the cutting process. Please note that this process incurs mold fees.

Currently, we offer over 300 card molds of various sizes, which can accommodate a wide range of design requirements. However, if your card size falls outside these standard molds, it means you’ll require a custom mold, which will involve an additional customization fee.

When it comes to the gluing of cardboard boxes, our machinery handles most of the gluing automatically. However, if your box design is exceptionally intricate, manual gluing may be necessary, significantly increasing the cost.

- Assembly and packaging

This phase encompasses the meticulous organization of all cards and components, shrink-wrapping, placement into game card boxes, and the subsequent sealing of these boxes. Much of this process relies on manual labor, and the cost can vary significantly depending on the number of components involved.

Additionally, this stage involves the careful placement of the card games into shipping boxes. It’s essential that these shipping cartons consist of at least five layers of thickness to ensure the protection of the merchandise.

This is a crucial precaution since many games are susceptible to damage during shipping. Shipping insurance typically only covers damage when the carton is of higher quality.

In addition to comprehending production costs, selecting the right card game printing manufacturer is equally vital. Essentially, there are two types of manufacturers to consider: print-on-demand (POD) manufacturers and mass manufacturers.

What Is a Print On Demand (POD) Manufacturer?

Print-on-demand (POD) manufacturers specialize in producing small game batches, often starting as low as just one deck of cards. They serve as an excellent choice for game designers aiming to create a limited-edition game before launching a crowdfunding campaign.

POD manufacturers employ digital printing technology, CNC cutting, and manual bonding and coating processes to craft games on a per-order basis. This approach eliminates the need for maintaining large inventories and specialized machinery.

However, one drawback of using a POD manufacturer is that you’re responsible for handling the artwork setup yourself. This can pose a challenge for designers who aren’t well-versed in the technical intricacies of print production.

Furthermore, it’s important to note that the dimensions used in POD paper sheets are fixed and cannot be customized to accommodate larger or smaller game components. This limitation arises from the considerable expense involved in creating molds for the manufacturing process, and it’s not feasible for low-volume products produced by POD manufacturers.

What Is Mass Manufacturer?

Mass manufacturers specialize in the production of high volumes of games. They employ large-scale manufacturing techniques like offset printing to create game components, granting greater flexibility for customization, including the capacity to craft both larger and smaller gaming elements.

Leading card game manufacturers, such as Komai, frequently maintain in-house graphic design teams capable of assisting with artwork setup and providing expert printing guidance for your game.

One of the primary advantages of partnering with large-scale manufacturers lies in their ability to manufacture games at a reduced unit cost. This cost efficiency is achieved through economies of scale, as they produce playing cards in substantial quantities.

Additionally, these manufacturers often cultivate enduring relationships with raw material suppliers and couriers, effectively curbing material and transportation expenses.

Furthermore, opting for mass manufacturers can yield benefits such as financing options and discounts.

For instance, Komai may offer a payment scheme involving a 30% deposit upon booking and the remaining 70% upon order completion. Collaborating with us on Kickstarter projects may also qualify you for a 6% factory discount.

If you want to know more details about tips to save card game printing costs, please check out Optimize Your Trading Card Printing Costs.