Printing Technology

首页 » Printing Technology

Make Your Own Game Cards Print Out With KOMAI

At KOMAI Company, we provide a variety of advanced printing process technologies, including CMYK printing, spot color printing, relief or embossing printing, hot stamping, holography and edge grinding, etc. These technologies are widely used in the production process of customized cards and customized boxes to meet your various personalized needs.

Please note that any printing process cannot guarantee 100% color difference. The actual printing color may be affected by various factors such as equipment conditions, ink quality, environmental temperature and humidity, storage conditions, and subjective feelings. However, we promise to do our best to reduce the color difference within the scope you allow to ensure that the quality of the final product meets your expectations.

Our professional team is dedicated to providing you with quality printing services to ensure your custom cards and boxes stand out in the market. If you have any questions or needs, please feel free to contact us.

KOMAI’s printing process technology

CMYK printing

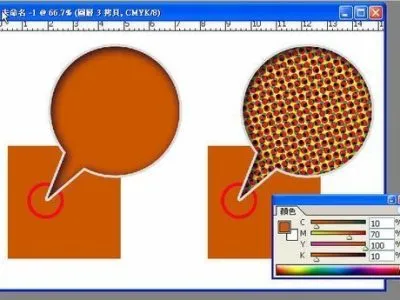

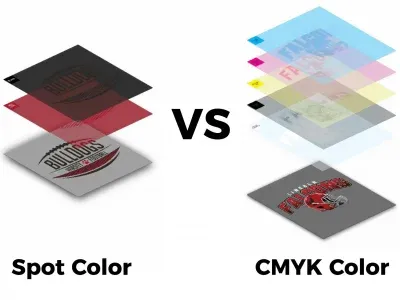

What is CMYK printing? CMYK printing is a standard color technology for full-color printing and is widely used in custom card printing. By mixing four basic colors (cyan, magenta, yellow and black), CMYK printing is able to achieve a variety of independent colors, resulting in millions of shades and many more independent colors. Therefore, it is also called “CMYK color printing” by us.

However, since CMYK printing involves mixing four colors of ink, slight differences in color may occur during actual printing. When you need almost 100% accurate color, we recommend you choose spot color printing. Click “Color Settings” to learn more about CMYK design details.

Spot color printing

Spot color printing uses a specially formulated ink rather than a mixture of four CMYK inks, so its color options are much richer than CMYK. Today, most printers refer to Pantone color cards and color codes to create or select spot colors.

Spot color printing plays an important role as an identifier in a project and is essential for creating uniqueness and protecting a proprietary product. However, spot color printing typically costs more than CMYK printing because it requires additional printer setup and platemaking processes.

Printing ink

Ink is the core raw material in the printing process. In order to promote sustainable development, we mainly use environmentally friendly inks for printing. However, if your project has specific needs, we also offer a variety of specialty ink options, such as metallic inks, anti-counterfeiting inks, and more.

In addition, in order to ensure product quality and safety, all our inks can pass CPC, CE-EN71, UKCA, SOR, etc. tests.

Hot stamping printing

Foil stamping is a decorative printing technology that usually includes three common effects: glossy, matte and holographic. Each effect is available in a variety of color options, such as gold, silver, and more. In addition to standard colors and patterns, foil stamping can also be personalized for large quantities or specific requirements.

The main purpose of using foil stamping is to add an eye-catching visual effect to your cards. However, it is important to note that foil stamping may reduce the smoothness of the card, causing some difficulty when shuffling or cutting.

We have 9 foil stamping techniques suitable for custom card printing. Each of these technologies has its own characteristics, and you can choose the one that best suits your unique design needs. Whether it’s to enhance your brand image or enhance your product’s quality, foil stamping can bring a superior visual and tactile experience to your cards. If you want to know more about the specific hot stamping technology, you can contact us at any time.

Edging printing

Edge printing is a commonly used card decoration technology. According to different processing methods, it is mainly divided into two types: hot stamping edge and cold matte edge. Hot stamping edges include gold, silver, black, pink and other options, while cold matte edges present a unique texture.

These edging techniques not only add unique edge decoration to the cards, but also significantly enhance the class and texture of the entire product. Depending on the production process, edge grinding can be divided into two methods: heat treatment and cold treatment. Heat treatment is suitable for cards that have been treated with oil (such as varnish), while cold treatment is suitable for cards that have been treated with glue (such as lamination).

At KOMAI, our commonly used colors include gold, silver and holographic colors. If you require other color options, please feel free to ask us. We will be happy to provide you with professional edge printing services to ensure that your cards stand out in the market.

UV transfer technology

UV transfer technology is a method that utilizes UV transfer adhesives and the inherent non-sticky properties of metal to create diverse and unique patterns. Through this technology, we are able to present a variety of exquisite patterns such as CD patterns, sun patterns, 3D textures, cat-eye effects, etc. Not only do these patterns have excellent optical qualities, they also offer high hardness, abrasion resistance and excellent chemical resistance.

KOMAI company is committed to providing you with high-quality UV transfer services to ensure that your products stand out in the market. Our professional team will select the most suitable UV transfer printing technology based on your needs to add unique visual effects to your products. For more information about UV transfer printing technology, please feel free to contact us.

Relief printing and embossed printing

Relief printing and embossing printing both use molds or metal plates to imprint on the surface of the substrate to create a raised or depressed surface effect. This printing technology can transform 2D designs into visual and tactile 3D effects, adding a unique texture to the product.

Relief printing is often used to highlight names and logos, enhancing brand recognition and high-end feel through three-dimensional performance. Concave-convex printing is often used to emphasize elements such as borders, underlines, and background patterns, adding layering and detail to the overall design.

In addition, relief printing and concave and convex printing can also be combined with other special technologies, such as hot stamping, etc., to create more unique and exquisite printing effects. KOMAI company provides you with professional relief printing and embossed printing services to ensure that your products stand out in the market.

Are you ready to start your innovation journey?

We aspire to be the world’s leading card manufacturer. We understand the importance of quality and will never sacrifice quality for the sake of quantity.

Let our team of professionals bring your personalized playing cards, tarot decks or table game cards to life. Here, your imagination is almost limitless and the customization possibilities are endless.

If you are eager to learn more about our customized services, please feel free to contact us. We eagerly look forward to working with you to realize your creative vision.