Surface Finishing Styles

首页 » Surface Finishing

Topcoat, also known as varnish, is a paint process applied to the surfaces of contrasts, boxes, and brochures. It not only improves the glassiness and smoothness of the surface, but also makes it colorfast, scratch-resistant and moisture-proof. With the current urgent emphasis on environmental protection, varnish-treated packages are more environmentally friendly and can be quickly absorbed by the soil. However, the overall glassiness of varnishes is relatively low compared to lamination processes.

Different types of lamination

Among the printing projects we offer, there are two finish styles to choose from: laminate and lacquer. Lamination is essentially an adhesive film that covers the surface of a card or box, and it has two effects: gloss lamination and matte lamination.

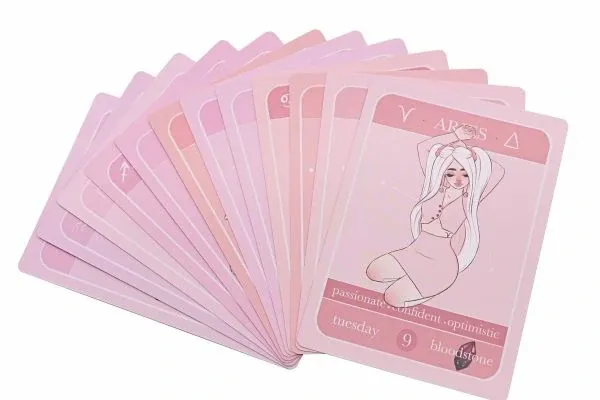

Gloss lamination creates a bright, vibrant and beautiful effect on the surface of a card or box. Typically, we would recommend gloss lamination for patterns that are lighter overall (like lots of pink, white, etc.). Not only is it very fade-resistant, water-resistant, rub-resistant, and scratch-resistant, but we offer regular glossy and holographic glossy finishes as regular options.

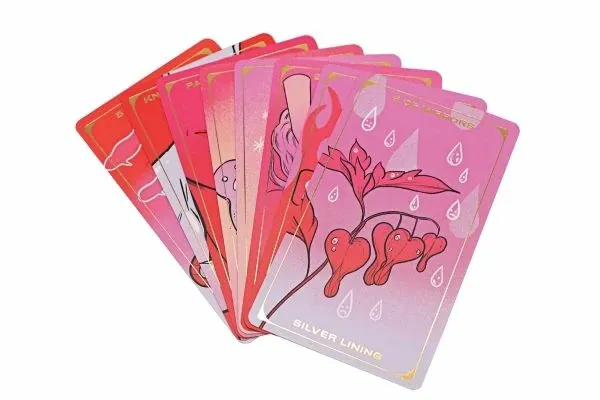

Matte lamination gives the surface of a card or box a soft and elegant matte effect. For patterns with darker overall colors (such as a lot of black, dark blue, etc.), matte lamination is recommended. In addition, matte lamination can also be combined with local UV, local hot stamping and other processes to present a more prominent visual effect. We offer a variety of matte laminates to meet your specific needs.

Choosing gloss lamination or matte lamination mainly depends on personal preference, and there is no absolute advantage or disadvantage between them. It should be noted that the lamination process conflicts with the edge grinding process. If you want a gold or matte edge effect, you can choose the corresponding varnish style.

Ordinary glossy lamination

- Effect: shiny

- Suitable for: playing cards, game cards, flashcards, paper boxes, lids and bottom boxes, etc.

Gloss lamination, also known as PP lamination or POP lamination, is a process that creates bright, vivid and beautiful effects. We recommend using this process on cards or box surfaces with lighter overall pattern colors (such as pink, white, etc.). It is fade-resistant, water-resistant, rub-resistant and scratch-resistant, but please note that gloss lamination cannot be used at the same time as the edge process.

Ordinary matte fit

- Effect: elegant

- Perfect for: tarot cards, oracles, affirmation cards, boxes, lids and bases, etc.

Our standard matte lamination is also fade-resistant and water-resistant, but there may be a risk of scratching or scuffing. If you have higher requirements for product durability, we recommend that you choose our higher-end anti-scratch frosting process, which can reduce the risk of scratches to a great extent. Scratch-resistant matte is a premium laminate option that offers a variety of pattern options, but comes with a slightly higher price tag.

Holographic film lamination

- Effect: super shiny

- Suitable for: tarot cards, game cards, collectible cards, magnetic boxes, etc.

The holographic treatment creates a very shiny and cool visual effect, giving the card or box a luxurious feel. It protects the card or box from warping, delamination, fading and moisture to a great extent. However, it is important to note that the holographic treatment may make the shuffling or cutting process less smooth. The minimum order quantity is 250 decks.

Scratch-resistant matte lamination

- Effect: non-fading, waterproof, scratch-proof

- Suitable for: tarot cards, oracles, affirmation cards, magnetic boxes, lid and bottom boxes, etc.

It uses a special lamination technology that has excellent visual effects and is superior to ordinary matte lamination in terms of wear resistance. This process is particularly suitable for large areas of solid color card surfaces, such as black and red, and can effectively prevent scratches and wear, providing more comprehensive protection for the card.

Silk matte laminate

- Effect: smooth touch

- Suitable for: tarot cards, oracles, affirmation cards, magnetic boxes, lid and bottom boxes, etc.

This advanced coating has the unique property of striking a balance between gloss and matte for a smooth feel, durability and ease of writing. When combined with the local UV process, it can produce a strong contrast effect and further enhance the visual effect and texture of the card.

Different types of varnish

Varnish is a coating applied to printed artwork during or after printing to enhance the appearance or protect the work from wear, scratches, and moisture and chemicals. However, the overall gloss of the varnish finish is lower compared to the lamination process described above.

Next, we’ll show you four clearcoat finish options in order from low gloss to high gloss:

- Ordinary matte varnish/water-based topcoat

- Butter varnish/semi-matt varnish

- Ordinary glossy varnish

- UV gloss varnish

Ordinary matte varnish

Regular matte varnish, also known as water-based varnish or water-based clearcoat, is a cost-effective coating option.

It gives your prints a less glossy surface texture, making colors and images appear softer and more detailed, while improving text legibility. This varnish does not contain organic solvents, heavy metals and toxic substances, so it has no pungent odor and is very friendly to the human body and the environment.

Regular matte varnish protects the surface of your card or box from fingerprints and effectively prevents scratches and scuffs. It is an ideal choice, especially for applications that require improved appearance and protection of printed matter.

UV varnish

UV varnish is one of the most commonly chosen effects in print production. It dries and cures quickly by exposing the coating to UV light, resulting in an ultra-high gloss surface.

Compared with other processes, UV varnish has the highest gloss and is especially suitable for dark-colored prints. Additionally, it offers excellent abrasion resistance and clarity, making prints more durable. At the same time, UV varnish is a recyclable and environmentally friendly material that meets the requirements of modern green printing.

If you don’t want the entire card surface or box surface to be too dazzling, we can also use local UV printing technology. This technique highlights key details, making the print more eye-catching while maintaining its overall beauty.

Ordinary varnish

Plain varnish is a standard gloss effect with basic dust and water resistance that makes colors look brighter and richer.

It is commonly used to create printed matter such as regular playing cards and flashcards. However, for materials such as PVC cardboard, color fading may occur because the surface is too smooth. Therefore, when choosing to use ordinary varnish, it is necessary to comprehensively consider the specific materials and uses.

Cream varnish

The cream varnish finished surface has a semi-matt varnish effect and is particularly suitable for high-end applications such as casino playing cards, cardistry playing cards and magic playing cards.

While ensuring an elegant appearance, the cream varnish also provides superior smoothness, feel and shuffling, cutting experience. This varnish not only makes the playing cards look more refined, but also improves the feel and ease of use, creating a more enjoyable experience for players.

Linen texture imprint

Linen texture embossing is a unique decorative effect often used in the production of high-end playing cards and game cards. In the “Playing Card Stock Types” section we offer a variety of options.

Among them, the touch and texture of linen textured cardstock may be slightly weakened after printing and other surface treatments. If you want a more pronounced tactile and textured effect, we recommend starting with a smooth cardstock and then adding a linen texture stamp.

After the printing is complete, a post-processing linen texture embossing is required. In this step, the paper is pressed under a heavy metal roller with a pattern of crossed lines, and the pressure of the roller etches the lines into the paper. This crafting not only enhances the tactility and beauty of the card, but also adds a unique artistic flair to it.

Are you ready to start your innovation journey?

We aspire to be the world’s leading card manufacturer. We understand the importance of quality and will never sacrifice quality for the sake of quantity.

Let our team of professionals bring your personalized playing cards, tarot decks or table game cards to life. Here, your imagination is almost limitless and the customization possibilities are endless.

If you are eager to learn more about our customized services, please feel free to contact us. We eagerly look forward to working with you to realize your creative vision.